Search Product

Search here for what you are looking for:

- Hot:

Send Inquiry

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Search here for what you are looking for:

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Packaging Scheme for Daily Chemical Products

Often used in chemical powder refinement, automatic packaging. High content monomer (amygdalin, puerarin, luteolin, curcumin, etc.) plant extract (aloe extract, wolfberry extract, black garlic extract, yam extract, etc.) chemical intermediates (nicotinamide mononucleotide (NMN), 5-ALA phosphate, 5-amino acetyl propionic acid hydrochloride, etc.) SC record products (ginseng powder, pueraria powder, blueberry powder, bitter almond powder, green tea powder, etc.) organic products (cherry powder, chlorella powder, coconut powder, papaya powder, black sesame extract, etc

A. The bag packaging machine replaces the traditional manual packaging, realize the automation of product packaging production, improve the production efficiency of enterprises, and greatly reduce the product cost.

B. The machine shall meet the hygiene standards of food processing machinery. The parts and components of the machine in contact with the materials and packaging bags are processed with materials that meet the requirements of food hygiene to ensure the hygiene and safety of food.

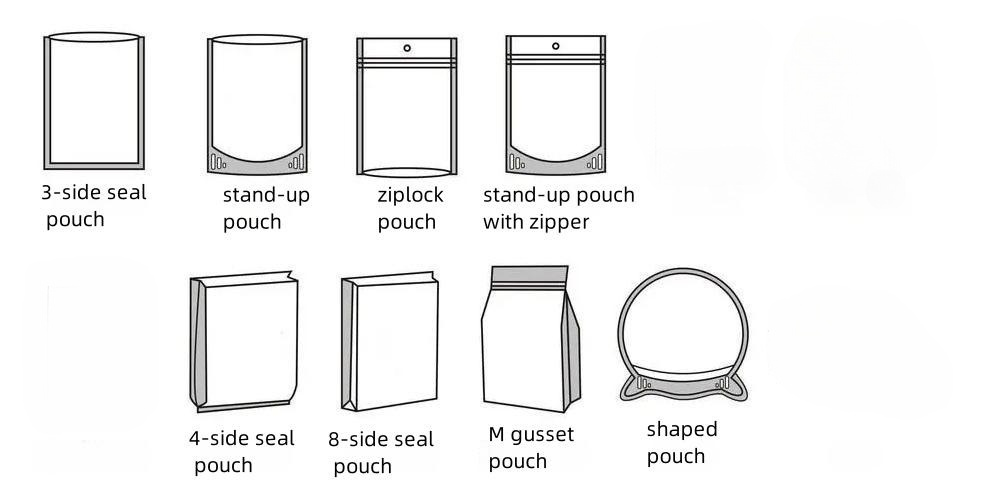

C. The packaging range of the machine is wide. According to the different packaging materials to choose different packing devices, you can package a variety of solid materials, liquid, sauce, powder, particles and other materials. Suitable for a wide range of packaging bags, for multi-layer composite film, single layer PE, PP and other made of prefabricated bags, paper bags can be applied. Perfect finished packaging bag pattern, good sealing quality, high grade.

D. The electrical control system adopts advanced PLC, with color POD (touch screen), man-machine interface friendly and easy to operate. Can quickly and easily adjust the rack width, packaging speed and other parameters.

E. The main motor is controlled by frequency conversion, and the frequency can be set on the color touch screen according to the actual needs. Machine with automatic detection device, can detect air pressure, temperature controller fault, bag on the machine, packaging bag mouth is open, can determine the machine status, control whether the machine code, filling device for filling, heat sealing device for sealing, to avoid waste of packaging materials and raw materials, greatly save cost

| Pouch packaging machine | |||

| model | LU8-200 | LU8-260 | LU8-300 |

| Mechanical station | Eight station | ||

| Pouch Size (mm) | Wide: 80-200 | Wide: 140-260 | Wide: 200-300 |

| Long length: 100-400 | |||

| tare | 10-2500g | ||

| Packaging speed | In the 25-60 packs / minute | In the 25-50 packs / minute | In the 10-30 packs / minute |

| Mechanical weight | 1400kg | 1500kg | 1700kg |

| voltage | 380V three-phase 50 HZ / 60 HZ | ||

| aggregate capacity | 2.5kw | 2.5kw | 3.0kw |

| Pouch packaging machine | ||

| model | LU8-420 | LU10-200 |

| Mechanical station | Eight station | Ten station |

| Pouch Size (mm) | Wide: 300-420 | Wide: 80-200 |

| Long length: 100-500 | Long length: 100-400 | |

| tare | 10-4000g | 10-2500g |

| Packaging speed | And 8-25 packs / min | In the 20-80 packs / minute |

| Mechanical weight | 2000kg | 1700kg |

| voltage | 380V three-phase 50 HZ / 60 HZ | |

| aggregate capacity | 3.0kw | 2.5kw |

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: When can the OEM machine be shipped?

A2: Depending on your specific project, it usually takes 30-45days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Processing demand survey

x