Search Product

Search here for what you are looking for:

- Hot:

Send Inquiry

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Search here for what you are looking for:

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Pet Food Packaging Scheme

particles, block, secondary packaging, food, pet food, pet supplies, hardware, medicine, etc.(Sauce and liquid can also be packaged)

1. Multi-station automatic bag machine it replaces manual packaging, for large enterprises, small and medium-sized enterprises to achieve packaging automation, the machine and materials or packaging bag contact parts are stainless steel or other materials that meet the requirements of food hygiene processing, to ensure the hygiene and safety of food, in line with food hygiene standards.

2. The machine adopts stable cam mechanical transmission technology, making the equipment run stable, with low failure rate and low energy consumption. At the same time, the machine adopts high-end circuit structure, man-machine interface (PLC + HMI) and other technologies, to achieve mechanical and electrical-body operation is convenient and simple.

3. All controls are realized by the automated software system, which facilitates function adjustment and technology upgrading, and never lags behind. Adopt the new German PLC control system. Adopt frequency converter without stage variable speed, the main motor, PLC, frequency converter, sensor, relay, contactor, pneumatic components are the international well-known brands;

4. The packaging machine implements self-automatic detection, information feedback and other functions, and the fault display is clear at a glance, with high photosensitive electric eye tracking. If there is no bag or the bag is not opened during production operation, the detection device does not fill or seal, and the operation status is displayed in real time and is automatically stopped. Save the packaging materials and raw materials, to ensure the packaging site environment.

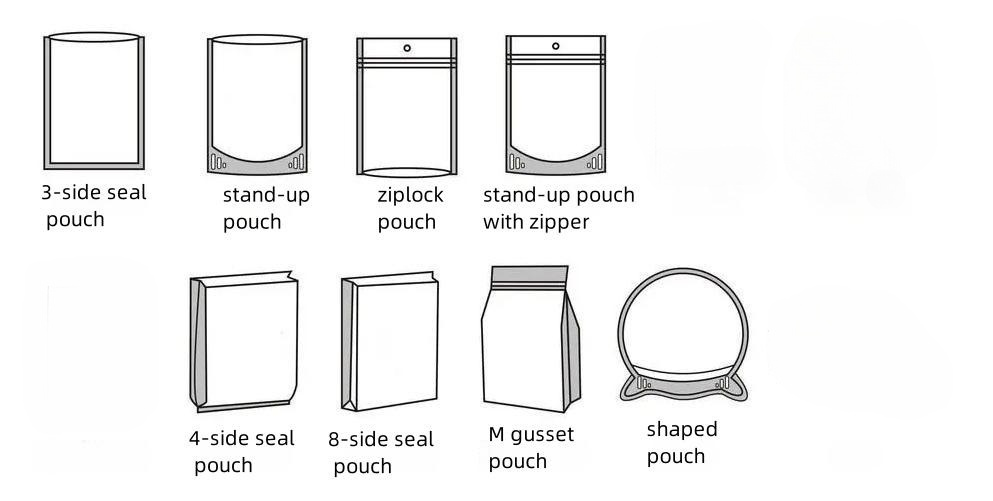

5. Packaging bags are suitable for a wide range of packaging, and the prefabricated bags and paper bags made of single-layer PE, PE composite material, CPP composite material, aluminum foil and other materials made of multi-layer composite film can be packaged.

6. The loss of packaging material is low, the machine is prefabricated bag, packaging bag pattern is perfect, the sealing quality is good, so as to improve the product grade.

7. A variety of bag delivery methods, bag storage device can store more packaging bags, the quality of low requirements, bag,. The bag rate is high.

8. Operating noise of the whole machine: the operating noise of the equipment is within 70 db (1m, outside the range).

9. The equipment seal shall be sealed by constant temperature.

10. Open the bag by mechanically opening the chain and vacuum the bag.

11. Packaging machine control and measurement to release material action, do not waste materials.

12. According to the size of the bag, equipped with appropriate stainless steel hopper, the hopper replacement is convenient.

13. Equipment with vibration device to ensure that the sealing material will not occur in the process of material packaging.

14. The equipment is equipped with a safety protection door, which is made of transparent plexiglass.

Particle, block, secondary packaging, food, pet food, pet supplies, hardware, medicine, etc.(Sauce and liquid can also be packaged)

In order to seek the most taste, nutrition, appearance and shelf life, pet food requires the outer packaging more and more high. Prefabricated bags not only improve the product grade, but also better preserve products with zipper bags or small inner bags.

| Pouch packaging machine | |||

| model | LU8-200 | LU8-260 | LU8-300 |

| Mechanical station | Eight station | ||

| Pouch Size (mm) | Wide: 80-200 | Wide: 140-260 | Wide: 200-300 |

| Long length: 100-400 | |||

| tare | 10-2500g | ||

| Packaging speed | In the 25-60 packs / minute | In the 25-50 packs / minute | In the 10-30 packs / minute |

| Mechanical weight | 1400kg | 1500kg | 1700kg |

| voltage | 380V three-phase 50 HZ / 60 HZ | ||

| aggregate capacity | 2.5kw | 2.5kw | 3.0kw |

| Pouch packaging machine | ||

| model | LU8-420 | LU10-200 |

| Mechanical station | Eight station | Ten station |

| Pouch Size (mm) | Wide: 300-420 | Wide: 80-200 |

| Long length: 100-500 | Long length: 100-400 | |

| tare | 10-4000g | 10-2500g |

| Packaging speed | And 8-25 packs / minute | In the 20-80 packs / minute |

| Mechanical weight | 2000kg | 1700kg |

| voltage | 380V three-phase 50 HZ / 60 HZ | |

| aggregate capacity | 3.0kw | 2.5kw |

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: When can the OEM machine be shipped?

A2: Depending on your specific project, it usually takes 30-45days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Hot tag: Pet Food Packaging Scheme Manufacturers&Suppliers Factory China.

Processing demand survey

x